Why DHA Filter’s Pleated Filter Bags Are the Smart Choice for High-Efficiency Dust Collection

The successful operation of cement & steel production, food processing, woodworking and pharmaceuticals industries depends on effective dust collection. These sectors require strong and highly efficient filtration systems to ensure their processes run smoothly. The absence of proper air filtration creates dangers to worker health and results in regulatory non-compliance while damaging equipment and creating extended production stoppages. The Pleated Filter Bags from DHA Filter represent an advanced solution for high-efficiency dust collection systems that need dependable performance and extended lifespan together with outstanding filtration capabilities.

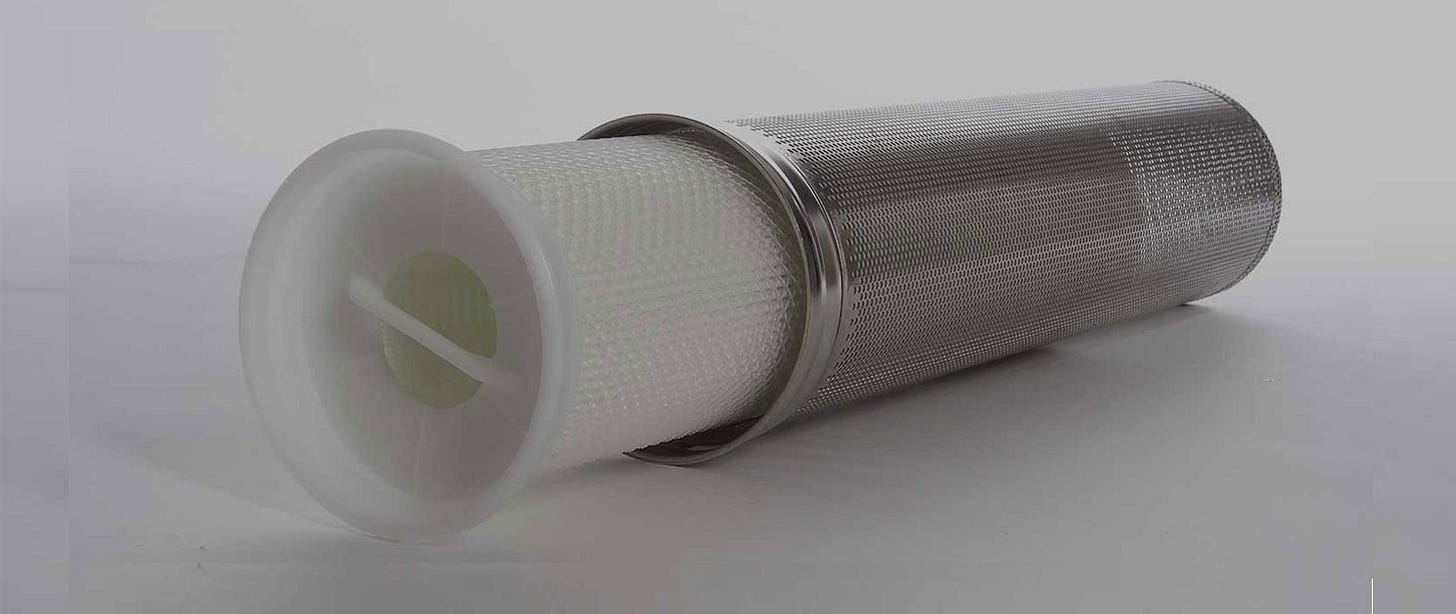

More Surface Area, Less Downtime

The primary purpose of DHA Filter’s pleated filter bags is to optimize dust collection efficiency while keeping filter housing dimensions constant. The pleated filter bag design expands its filtration area by three times when installed in the same dimensions as traditional cylindrical filter bags. The design structure of pleated filter bags enables improved dust retention capacity and longer operating periods between maintenance stops which results in reduced replacement needs and shorter downtime.

The increased operational hours along with reduced maintenance expenses result from these filter bags. High-volume dust environments that use this technology will generate significant annual cost reductions.

Enhanced Filtration Efficiency

DHA’s pleated filter bags feature filtration media which provides top-notch efficiency in capturing small particles while preserving maximum airflow. The filter bags exist in multiple materials along with different micron ratings to fulfill requirements across various industrial applications.

DHA’s pleated filter bags provide top-notch filtration performance while minimizing air pressure loss when dealing with abrasive dust and fine powders and sticky particles. The system maintains efficiency while staying within workplace and environmental safety requirements because of this feature.

Easy Integration with Existing Systems

DHA Filter’s pleated bags provide a major benefit because they integrate seamlessly with current baghouse systems. The filter bags from DHA Filter are built to substitute conventional filter bags and cages without needing any adjustments to your dust collection system. The upgrade process becomes easier and less expensive and simpler because of this design which enhances system performance.

The transition to pleated filter bags gives facilities an immediate performance boost through enhanced filtration without requiring complete system replacement when their current filter capacity no longer meets their needs.

Built for Durability and Demanding Conditions

Premium materials in DHA Filter’s pleated bags provide resistance against chemical breakdown and both abrasion and high temperature exposure. The strong construction materials ensure these products will maintain their performance levels throughout extreme industrial conditions.

The pleated bags offer a selection of features including pulse-jet cleaning compatibility and anti-static or hydrophobic finishes which meet specific application requirements. DHA Filter maintains quality assurance processes for their products which deliver consistent performance along with dependable results.

A Trusted Filtration Partner

DHA Filter established itself as a company through decades of service innovation while delivering premium quality products. Clients receive personalized filter recommendations from the DHA team who understand their operational requirements.

The pleated filter bags from DHA Filter represent a smart and forward-thinking solution for facilities that want to improve their dust collection system efficiency while reducing operational expenses.